Welcome to Juyiheng Iron and steel

Tel : +8615964533262 E-mail : freya@fhuametal.com

Duplex Stainless Pipe

Parameter: 1/2''~48'', SCH5~SCHXXS

End: Beveled End, Plain End

Service: Cutting, Welding, Fabricated, Customized

hiddenValue

PRODUCT DETAILS

Description

Duplex Stainless Steel (DSS) including grades duplex 2205(S31803) and super duplex, they are commonly consist of 50% ferrite and 50% austenite, and generally requires not less than 30%. Duplex stainless steel has good welding performance and high strength. Compared with austenitic stainless steel, it is about double yield strength of stainless steel 316, 317 etc., it make the equipment lighter and stronger. Duplex stainless steel pipe has very good resistance to localized corrosion and stress corrosion cracking. Duplex steel is not intended to be used at temperatures above 300°C due to embrittlement, the continuous use temperature is from -50 to 250 °C.

Typical Properties:

Low cost

Alternative to high nickel based alloys

High strength

Corrosion resistant

Very hard machining

Applications

2205, used in chemical processing, oil and gas processing equipment, marine and other high chloride environments, effluent scrubbing systems, pulp and paper industry, cargo tanks for ships and trucks, food processing equipment, biofuels plant.

2304, used in chloride containing environments, welded pipe systems, transportation, heat exchanger tubes, construction, pressure vessels, caustic solutions and the food industry.

2507, used in oil and gas industry equipment, offshore platforms, chemical process industries, desalination plants, mechanical and structural components and power industry FGD systems.

Specification&Standard

|

Pipe OD |

Pipe WT |

in. |

Sch |

Kg/m |

|

13.72 |

1.65 |

1/4 |

10S |

0.50 |

|

13.72 |

2.24 |

1/4 |

40S |

0.64 |

|

13.72 |

3.02 |

1/4 |

80S |

0.81 |

|

17.15 |

1.65 |

3/8 |

10S |

0.64 |

|

17.15 |

2.31 |

3/8 |

40S |

0.86 |

|

17.15 |

3.20 |

3/8 |

80S |

1.12 |

|

21.34 |

2.11 |

1/2 |

10S |

1.02 |

|

21.34 |

2.77 |

1/2 |

40S |

1.29 |

|

21.34 |

3.73 |

1/2 |

80S |

1.65 |

|

26.67 |

2.11 |

3/4 |

10S |

1.30 |

|

26.67 |

2.87 |

3/4 |

40S |

1.71 |

|

26.67 |

3.91 |

3/4 |

80S |

2.23 |

|

33.40 |

2.77 |

1 |

10S |

2.13 |

|

33.40 |

3.38 |

1 |

40S |

2.54 |

|

33.40 |

4.55 |

1 |

80S |

3.29 |

|

33.40 |

6.352) |

1 |

160 |

4.30 |

|

42.16 |

2.77 |

1¼ |

10S |

2.73 |

|

42.16 |

3.56 |

1¼ |

40S |

3.44 |

|

42.16 |

4.85 |

1¼ |

80S |

4.53 |

|

42.16 |

6.352) |

1¼ |

160 |

5.69 |

|

48.26 |

2.77 |

1½ |

10S |

3.16 |

|

48.26 |

3.68 |

1½ |

40S |

4.11 |

|

48.26 |

5.08 |

1½ |

80S |

5.49 |

|

60.33 |

2.77 |

2 |

10S |

3.99 |

|

60.33 |

3.91 |

2 |

40S |

5.52 |

|

60.33 |

5.54 |

2 |

80S |

7.60 |

|

60.33 |

8.742) |

2 |

160 |

11.29 |

|

73.03 |

3.05 |

2½ |

10S |

5.35 |

|

73.03 |

5.16 |

2½ |

40S |

8.77 |

|

73.03 |

7.01 |

2½ |

80S |

11.59 |

|

88.90 |

3.05 |

3 |

10S |

6.56 |

|

88.90 |

5.49 |

3 |

40S |

11.47 |

|

88.90 |

7.62 |

3 |

80S |

15.51 |

|

88.90 |

11.132) |

3 |

160 |

21.67 |

|

101.60 |

3.05 |

3½ |

10S |

7.53 |

|

101.60 |

5.74 |

3½ |

40S |

13.78 |

|

101.60 |

8.08 |

3½ |

80S |

18.92 |

|

114.30 |

3.05 |

4 |

10S |

8.50 |

|

114.30 |

6.02 |

4 |

40S |

16.32 |

|

114.30 |

8.56 |

4 |

80S |

22.67 |

|

114.30 |

13.492) |

4 |

160 |

34.05 |

|

141.30 |

6.55 |

5 |

40S |

22.10 |

|

141.30 |

9.53 |

5 |

80S |

31.44 |

|

141.30 |

15.882) |

5 |

160 |

49.87 |

|

168.28 |

3.4 |

6 |

10S |

14.04 |

|

168.28 |

7.11 |

6 |

40S |

28.69 |

|

168.28 |

10.97 |

6 |

80S |

43.21 |

|

168.28 |

14.27 |

6 |

120 |

54.75 |

|

168.28 |

18.262) |

6 |

160 |

68.59 |

|

219.08 |

8.18 |

8 |

40S |

43.20 |

|

219.08 |

12.7 |

8 |

80S |

65.63 |

|

219.08 |

18.23 |

8 |

120 |

91.30 |

|

219.08 |

23.012) |

8 |

160 |

112.97 |

Note: For sizes other than given, please check with our office for further confirmation.

Grade Available : UNS S31803, UNS S32205, UNS S31500, UNS S32304, UNS S32750, UNS S32760

Specification :

ASTM A789 (ASME SA789): Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

ASTM A790 (ASME SA790): Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

ASTM A928 - Standard Specification for Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded with Addition of Filler Metal

The specification of EN 10216-5 is available.

|

Grade |

Chemical Composition |

|||||||||

|

C (max) |

Si (max) |

Mn (max) |

P (max) |

S (max) |

Cr |

Ni |

Mo |

N |

Cu |

|

|

S32750 |

0.030 |

0.8 |

1.2 |

0.030 |

0.015 |

24.0-26.0 |

6.8-8.0 |

3.0-5.0 |

0.24-0.32 |

0.5 max |

|

S13803 |

0.030 |

1.0 |

2.0 |

0.030 |

0.020 |

21.0-23.0 |

4.50-6.50 |

2.50-3.50 |

0.08-0.20 |

|

Chemical Composition

|

Steel No. |

Standard No. |

Type |

Chemical composition |

Other |

||||||||||||

|

C |

Si |

S |

P |

Mn |

Cr |

Ni |

Mo |

Other |

ób |

ós |

δ5 |

HB |

||||

|

0Cr26Ni5Mo2 |

GB1220 |

Bar |

0.08 |

1 |

0.03 |

0.035 |

1.5 |

23-28 |

3-6 |

1-3 |

|

590 |

390 |

18 |

277 |

ψ%:40 |

|

0Cr26Ni5Mo2 |

GB4237 |

Plate |

0.08 |

1 |

0.03 |

0.035 |

1.5 |

23-28 |

3-6 |

1-3 |

|

590 |

390 |

18 |

277 |

|

|

0Cr26Ni5Mo2 |

GB/T14976 |

Pipe |

0.08 |

1 |

0.03 |

0.035 |

1.5 |

23-28 |

3-6 |

1-3 |

|

590 |

390 |

18 |

|

|

|

00Cr18Ni5Mo3Si2 |

GB1220 |

Bar |

0.03 |

1.3-2 |

0.03 |

0.035 |

1.2-1.6 |

18-19.5 |

4.5-5.5 |

2.5-3 |

|

590 |

390 |

20 |

|

ψ%:40 |

|

00Cr18Ni5Mo3Si2 |

GB4237 |

Plate |

0.03 |

1.3-2 |

0.03 |

0.03 |

1.2-1.6 |

18-19.5 |

4.5-5.5 |

2.5-3 |

N:0.1 |

590 |

390 |

20 |

|

|

|

HDR |

Q/SJB11-99 |

Pipe |

0.03 |

1 |

0.03 |

0.035 |

2 |

23-26 |

4.5-7.5 |

2-3 |

|

650 |

450 |

27 |

|

|

Physical Propertie

|

Grade |

Physical Propertie |

|||

|

Y.S. MPa (min) |

T.S. MPa (min) |

Elongation % |

Hardness HRC |

|

|

S32750 |

550 |

800 |

15 |

31 |

|

S13803 |

450 |

620 |

25 |

31 |

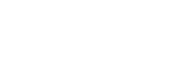

Process

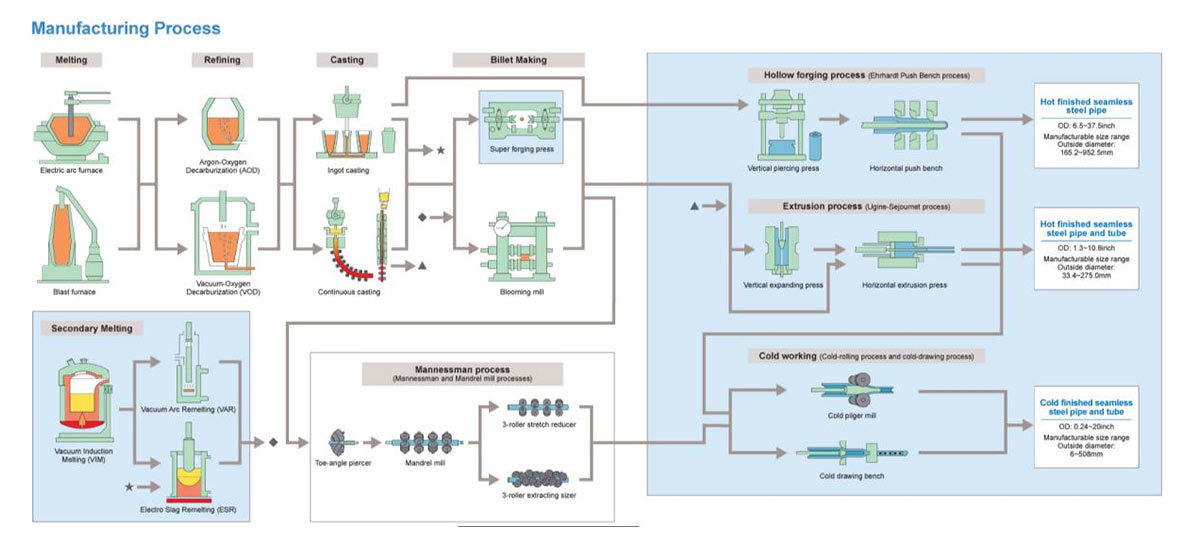

Packing

Storage video

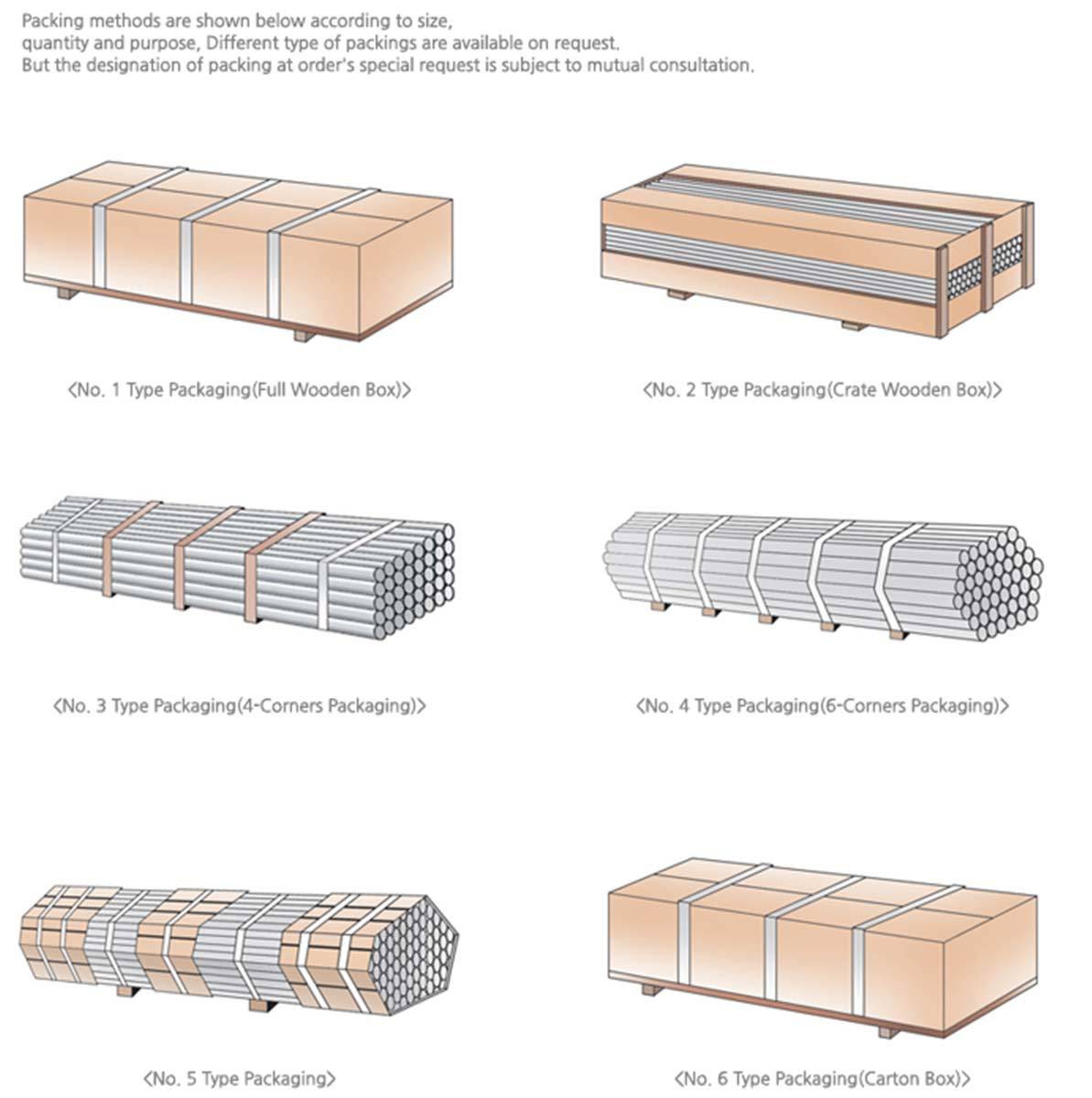

Warehouse storage

The group company and factory cover an area of more than 800 mu, with more than 1,500 employees, and its business covers more than 20 countries and regions around the world. Xinghan Group is committed to developing new types of steel products and building a first-class coated sheet and steel manufacturing enterprise with international competitiveness. Xinghan Group hopes to grow into a widely respected and sustainable global resource-based enterprise through continuous pursuit of excellence, create better social, economic and environmental benefits, and bring more competitive value returns to employees and customers.

Packing and delivery

The company has major production lines such as pickling, cold rolling, hot dip galvanizing, hot dip galvanizing, thick plate galvanizing and color coating, forming an annual production capacity of 1 million tons of pickling coil, 1 million tons of cold rolled sheet and 900,000 tons of hot dip galvanized sheet. Galvanized and hot-dip galvanized aluminum zinc silicon steel sheet scale 450,000 tons thick galvanized steel plate scale 300,000 tons color coated steel plate scale is one of the largest steel and non-ferrous metal smelting and processing suppliers in Shandong Province.

Customer visit

The company adheres to the development strategy of "seeking development by science and technology, seeking efficiency by management", adheres to the core values of "people-oriented, integrity, responsibility and excellence", adheres to the development system of "green products and green industry", "promotes high-quality beyond development in an all-round way", and realizes the vision of "building a first-class aluminum processing service enterprise with international competitiveness".

Application field

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision machining, auto parts, machinery, electronic products, molds, medical treatment Equipment, construction, decoration, etc.

RELATED PRODUCTS

GET A FREE QUOTE