Welcome to Juyiheng Iron and steel

Tel : +8615964533262 E-mail : freya@fhuametal.com

Nickel Alloy Pipe

Sizes:1 / 8" NB - 24" NB

Thickness:0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type:Seamless / ERW / Welded / Fabricated / CDW

Length:Single Random, Double Random & Required Length

End:Plain End, Beveled End, Threaded

hiddenValue

PRODUCT DETAILS

Description

Monel >> Monel 400, Monel K-500, Monel R405

Inconel >> Inconel 600, Inconel 601, Inconel 625, Inconel 617, Inconel 690, Inconel 718,

Inconel X-750, Inconel 926

inconel 718 forged bar, Inconel 718 round bar Price ,Astm B637,Astm B637 Forged Round Bar Inconel 718 price

Incoloy >> Incoloy A-286, Incoloy 800, Incoloy 800H, Incoloy 800HT, Incoloy 825, Incoloy 926, Nimonic 75, Nimonic 80A, Nimonic 263, Nimonic 90, Incoloy 901, Incoloy 925

inconel 718 forged bar, Inconel 718 round bar Price ,Astm B637,Astm B637 Forged Round Bar Inconel 718 price

Hastelloy >> Hastelloy C-276, Hastelloy C-22, Hastelloy C-4, Hastelloy B-2, Hastelloy B-3,

Hastelloy X, Hastelloy G, Hastelloy G2, Hastelloy G3, Hastelloy G30

inconel 718 forged bar, Inconel 718 round bar Price ,Astm B637,Astm B637 Forged Round Bar Inconel 718 price

Austenitic stainless steel >> 904L, Nitronic 60, XM-19, Nitronic 40, 316Ti, 316N, 316LN, 317,

317L, 310S, 253MA

inconel 718 forged bar, Inconel 718 round bar Price ,Astm B637,Astm B637 Forged Round Bar Inconel 718 price

DP Steel >> 254SMO, F50, 2205, F53, F55 (ZEROM 100) , F60, F61, F65

inconel 718 forged bar, Inconel 718 round bar Price ,Astm B637,Astm B637 Forged Round Bar Inconel 718 price

PH Steel >> 15-5PH, 17-4PH, 17-7PH

|

Designation |

Nearest Related Specification |

Description |

|

ALLOY C-276 |

ASTM B-574, 575, 619, 622, 626 |

Outstanding resistance to a variety of environments, including strong oxidisers, hot contaminated mineral acids, wet or dry chlorine contaminated media, acetic anhydride and sodium chloride solutions. |

|

NICKEL 200 |

ASTM B160-3, BS3072: NA11 |

Commercial wrought nickel; good mech. props; excel.resistance to many corrosion environments including foods, synthetic fibres and alkalis. |

|

MONEL* |

ASTM B127, 163-165, BS3072-6: NA13 |

Good resistance to corrosion by sea water, dilute sulphuric, chemical, steam and petroleum plant, marine and pickling equipment. |

|

MONEL* |

BS3072-6: NA18 QQ-N-286D |

Similar corrosion resistance to Monel Alloy 400, but amenable to precipitation-hardening to give high strength. For propeller and pump shafts, bolts, doctor blades and valves. |

|

INCONEL* |

ASTM-B163, 166, 168, BS 3072-6: NA14 |

Combines excellent high temp strength with resistance to oxidising, carburising, nitriding and reducing atmospheres. |

|

INCONEL* |

|

Improved alloy where maximum high temp strength and oxidation resistance required. Good sulphidation and carburising resistance. |

|

INCONEL* |

ASTM B443,444,446 |

For wet corrosive, high temp and cyrogenic service. High resistance to range of corrosive solutions including acids, salts and sea water where pitting, crevice or stress cracking may occur. Excellent for overlay and dissimilar metal welds. |

|

INCOLOY* |

BS 3072-6: NA17 |

A general purpose heat-resisting alloy with particular resistance to carburisation and alternating carburisation and oxidation. For furnace parts, heat-treatment and vitreous enamelling equipment. |

|

INCOLOY* |

ASTM B163, 407-9, BS 3072-16: NA15 |

Resistant to chloride-ion stress-corrosion cracking, excellent high temperature strength and immunity to Sigma phase formation. Widely used for petrochemical and high temperature process equipment. |

|

INCOLOY* |

ASTM BI63, B423-5, BS 3072-6: NA16 |

Developed for use in aggressive corrosive environments. Exceptional resistance to corrosion by acids and alkalis in reducing or oxidising conditions. It is resistant to stress corrosion cracking and pitting and used for chemical plant and pickling plant. |

|

DUPLEX STAINLESS |

ASTM A240, A47 9, A959 |

2507 is a duplex stainless steel with very high strength. It has very high resistance to uniform corrosion, pitting and crevice corrosion and to stress corrosion cracking. |

|

AUSTENITIC STAINLESS STEEL 310 (S31000) |

ASTM A240 |

A heat resistant austenitic stainless steel with better scaling resistance than standard grades. Usable to 1035°C in intermittent service, 1150°C in continuous service |

|

AUSTENITIC STAINLESS STEEL 253MA (S30815) |

ASTM A240 |

253 MA is microalloyed with rare earth metals (REM) for excellent heat resistance. Best used at 850-1100°C. Can become brittle at room temperature after service at 600-850°C. |

|

AUSTENITIC STAINLESS STEEL 254SMO (S31254) |

ASTM A240 |

Highly corrosion resistant austenitic stainless steel containing 6% molybdenum, plus copper. Pitting resistance equivalent =43. |

|

ALLOY 31 |

ASTM B625, B462, B649, B366, B626 |

An advanced super-austenitic, high-chromium 6% moybdenum corrosion resisting alloy. Bridges the cost/performance gap between Ni-Cr-Mo alloys and 300 series stainless steels. Is used in the chemical process and petrochemical industries. |

Specification&Standard

|

Nominal Pipe Size |

Outside diameter |

Wall thickness |

|||||

|

SCH 5S |

SCH 10S |

SCH STD (40S) |

SCH XS |

SCH 160S |

SCH XXS |

||

|

1/8" |

10.29 |

- |

1.24 |

1.73 |

2.41 |

- |

- |

|

1/4" |

13.72 |

- |

1.65 |

2.24 |

3.02 |

- |

- |

|

3/8" |

17.15 |

- |

1.65 |

2.31 |

3.20 |

- |

- |

|

1/2" |

21.34 |

1.65 |

2.11 |

2.77 |

3.73 |

4.75 |

7.47 |

|

3/4" |

26.67 |

1.65 |

2.11 |

2.87 |

3.91 |

5.54 |

7.82 |

|

1" |

33.40 |

1.65 |

2.77 |

3.38 |

4.55 |

6.35 |

9.09 |

|

1 1/4" |

42.16 |

1.65 |

2.77 |

3.56 |

4.85 |

6.35 |

9.70 |

|

1 1/2" |

48.26 |

1.65 |

2.77 |

3.68 |

5.08 |

7.14 |

10.16 |

|

2" |

60.33 |

1.65 |

2.77 |

3.91 |

5.54 |

8.71 |

11.07 |

|

2 1/2" |

73.03 |

2.11 |

3.05 |

5.16 |

7.01 |

9.53 |

14.02 |

|

3" |

88.90 |

2.11 |

3.05 |

5.49 |

7.62 |

11.13 |

15.24 |

|

3 1/2" |

101.60 |

2.11 |

3.05 |

5.74 |

8.08 |

- |

16.15 |

|

4" |

114.30 |

2.11 |

3.05 |

6.02 |

8.56 |

13.49 |

17.12 |

|

5" |

141.30 |

2.77 |

3.40 |

6.55 |

9.53 |

15.88 |

19.05 |

|

6" |

168.28 |

2.77 |

3.40 |

7.11 |

10.97 |

18.24 |

21.95 |

|

8" |

219.08 |

2.77 |

3.76 |

8.18 |

12.70 |

23.01 |

22.23 |

|

10" |

273.05 |

3.40 |

4.19 |

9.27 |

12.70 |

28.58 |

25.40 |

|

12" |

323.85 |

3.96 |

4.57 |

9.53 |

12.70 |

33.32 |

25.40 |

|

14" |

355.6 |

3.96 |

4.78 |

9.53 |

12.70 |

35.71 |

- |

|

16" |

406.4 |

4.19 |

4.78 |

9.53 |

12.70 |

40.46 |

- |

|

18" |

457.2 |

4.19 |

4.78 |

9.53 |

12.70 |

45.24 |

- |

|

20" |

508.0 |

4.78 |

5.54 |

9.53 |

12.70 |

49.99 |

- |

|

22" |

558.8 |

4.78 |

5.54 |

9.53 |

12.70 |

53.97 |

- |

|

24" |

609.6 |

5.54 |

6.35 |

9.53 |

12.70 |

59.51 |

- |

Note:The dimensions are in millimeters

|

Standard |

– ASTM A270,ASTM A249,ASTM A511,ASTM A778 ,ASTM A312,ASTM A358,ASTM A409,ASTM A213,ASTM A790,ASTM A268,ASTM A269,ASTM A554,ASTM B338,ASTM B673,ASTM B674,ASTM B677,ASTM B675, ASTM B676, ASTM B690,ASTM A928,ASME B36.19,ASME B36.10– EN10216-5,EN10217-7,DIN 17456,DIN 17458 |

|

Size Range |

OD: NPS 1/8 -80, BN 6 – 2000, 10.3 – 2030 , Alao capilaryWT: Sch5s-Sch160s, SchXXH, STD,XS,XXSLength: Customization |

|

Grade |

S32750, 00Cr25Ni7Mo4N, 022Cr25Ni7Mo4N, 1.441, 1.4307/1.4301/304L/3, S30408/S30403, 0Cr18Ni9DQ, 1.4948/304H, 07Cr19Ni10, S30409, 1.4948, 06Cr23Ni13, S30908, SUS309S, SUS310S, 1.4845, S31008, S31008S, 06Cr25Ni20, 0Cr25Ni20, 1.4401/1.4404/316/31, S31635, SUS316Ti, 1.4571, 1.4571/316Ti, S31703, 022Cr19Ni13Mo3, 00Cr17Ni12Mo2, S31703, SUS317L, 1.4438, S41008, SUS410S, 1.4, 06Cr13, S11306, 0Cr13, S42000, SUS420J1, 1.4021, SUS420J2, 1.4028, S43020, 430F, SUS430F, 1.4104, , 301, 302, 303, 305, 309, 310, 316, 317, 321, 347, 403, 405, 416, 431, 444, 2205, 2507, 304/304L, 304DQ, 304H, 309S, 310S, 316/316L, 316Ti, 317L, 410S, 420J1, 420J2, 430F, 254Smo, 1.4529, HC276, 800, 825, 600, 601, 718, 750, 400, 630, XM19, C4, S30815, S31254, 174PH, F51, F60, F53, S32760, 253MA, HC2000, 800H, 926, GH2132, GH4169, GH3030, GH3039, GH4151, N04400, HB3, 0Cr13Ni5Mo, N08367, N08810 |

|

ASTM B111 / ASME SB111 |

|

Standard Specification for Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock |

|

ASTM B161 / ASME SB161 |

|

Standard Specification for Nickel Seamless Pipe and Tube |

|

ASTM B163 / ASME SB163 |

|

Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes |

|

ASTM B165 / ASME SB165 |

|

Standard Specification for Nickel-Copper Alloy (UNS N04400)* Seamless Pipe and Tube |

|

ASTM B167 / ASME SB167 |

|

Standard Specification for Nickel-Chromium-Iron Alloys, Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617),and Nickel-Iron-Chromium-Tungsten Alloy (UNS N06674) Seamless Pipe and Tube |

|

ASTM B395 / ASME SB395 |

|

Standard Specification for U-Bend Seamless Copper and Copper Alloy Heat Exchanger and Condenser Tubes |

|

ASTM B407 |

|

Standard Specification for Nickel-Iron-Chromium Alloy Seamless Pipe and Tube |

|

ASTM B423 / ASME SB423 |

|

Standard Specification for Nickel-Chromium-Molybdenum-Columbium Alloys (UNS N06625 and UNS N06852) and Nickel-Chromium-Molybdenum-Silicon Alloy (UNS N06219) Pipe and Tube |

|

ASTM B444 / ASME SB444 |

|

Standard Specification for Nickel-Chromium-Molybdenum-Columbium Alloys (UNS N06625 and UNS N06852) and Nickel-Chromium-Molybdenum-Silicon Alloy (UNS N06219) Pipe and Tube |

|

ASTM B622 / ASME SB622 |

|

Standard Specification for Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube |

|

ASTM B668 / ASME SB668 |

|

Standard Specification for UNS N08028 and N08029 Seamless Pipe and Tube |

|

ASTM B677 / ASME SB677 |

|

Standard Specification for UNS N08925, UNS N08354, and UNS N08926 Seamless Pipe and Tube |

|

ASME SB690 / ASME SB690 |

|

Standard Specification for Iron-Nickel-Chromium-Molybdenum Alloys (UNS N08366 and UNS N08367) Seamless Pipe and Tube |

|

ASTM B705 / ASME SB705 |

|

Standard Specification for Nickel-Alloy (UNS N06625, N06219 and N08825) Welded Pipe |

|

ASTM B729 / ASME SB729 |

|

Standard Specification for seamless UNS N08020, UNS N08026, and UNS N08024 nickel alloy pipe and Tube |

|

ASTM B829 / ASME SB829 |

|

Standard Specification for General Requirements for Nickel and Nickel Alloys Seamless Pipe and Tube |

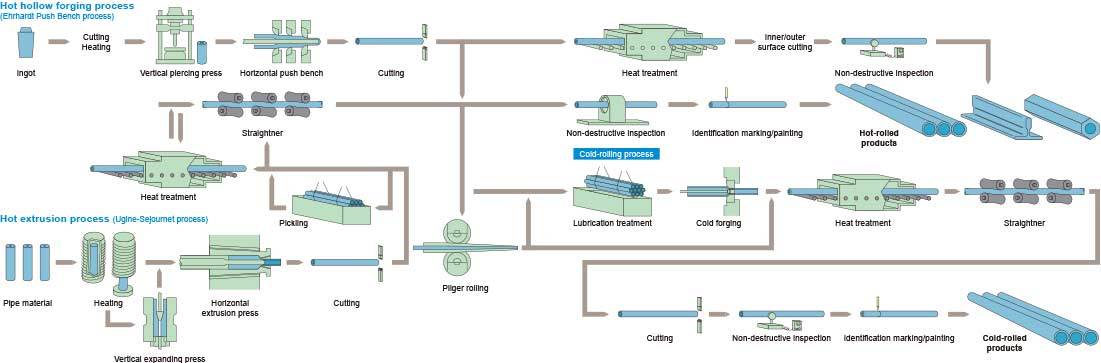

Process

Seamless steel pipe

Welded steel pipe

Storage video

Warehouse storage

The group company and factory cover an area of more than 800 mu, with more than 1,500 employees, and its business covers more than 20 countries and regions around the world. Xinghan Group is committed to developing new types of steel products and building a first-class coated sheet and steel manufacturing enterprise with international competitiveness. Xinghan Group hopes to grow into a widely respected and sustainable global resource-based enterprise through continuous pursuit of excellence, create better social, economic and environmental benefits, and bring more competitive value returns to employees and customers.

Packing and delivery

The company has major production lines such as pickling, cold rolling, hot dip galvanizing, hot dip galvanizing, thick plate galvanizing and color coating, forming an annual production capacity of 1 million tons of pickling coil, 1 million tons of cold rolled sheet and 900,000 tons of hot dip galvanized sheet. Galvanized and hot-dip galvanized aluminum zinc silicon steel sheet scale 450,000 tons thick galvanized steel plate scale 300,000 tons color coated steel plate scale is one of the largest steel and non-ferrous metal smelting and processing suppliers in Shandong Province.

Customer visit

The company adheres to the development strategy of "seeking development by science and technology, seeking efficiency by management", adheres to the core values of "people-oriented, integrity, responsibility and excellence", adheres to the development system of "green products and green industry", "promotes high-quality beyond development in an all-round way", and realizes the vision of "building a first-class aluminum processing service enterprise with international competitiveness".

Application field

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision machining, auto parts, machinery, electronic products, molds, medical treatment Equipment, construction, decoration, etc.

RELATED PRODUCTS

GET A FREE QUOTE